overview

At the forefront of digital transformation, we have developed sophisticated Artificial Intelligence and Machine Learning tools, to be integrated into our core offerings. This has advanced our products and is reshaping the future of the service and after-sales industry. Our AI capabilities are designed not just to automate trivial tasks, but to generate meaningful insights, aid in operational efficiency, and enhance customer satisfaction.

We believe that data is the new oil of innovation. Our robust digital infrastructure and our Service Management System (SMS), helped us to understand customer behaviour, identify patterns, and anticipate needs. This serves as the foundation for intelligent models that enables a shift from reactive to proactive service

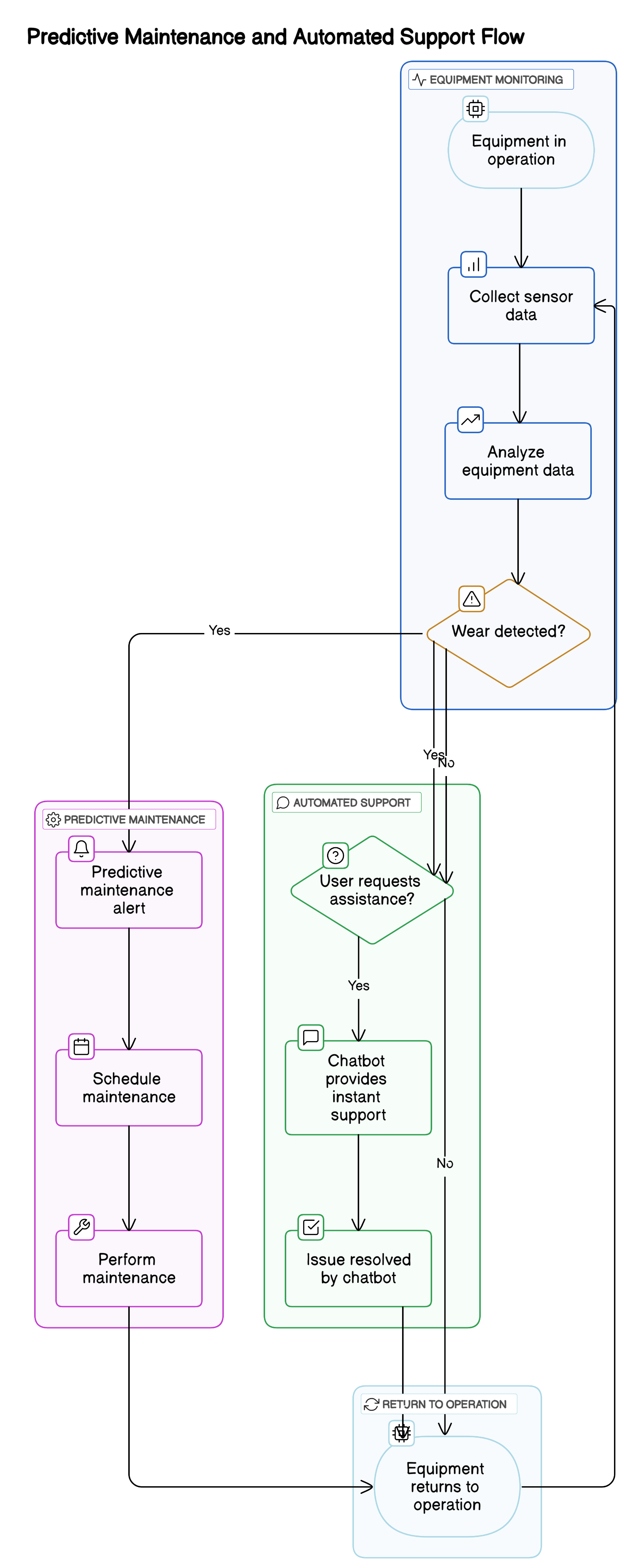

From predictive maintenance that prevents breakdowns before they occur, to smart troubleshooting that identifies and resolves issues faster, we are embedding intelligent systems into every touchpoint of the customer journey. Also, our IoT platform leverage AI inputs to deliver real-time diagnostics and emergency risk mitigation, resulting in improved equipment uptime and reduced service costs.

Subsequently, we recognize that every business has unique needs. That's why we are indulging in robust investment in developing and fine-tuning AI models tailored to specific use cases and industries. Whether it's forecasting demand, optimizing workforce deployment, or powering intelligent customer interactions, our AI solutions are adaptable, scalable, and impactful.

Through continuous innovation in AI and ML, we are not only enhancing the value of our own services but also empowering our clients to make quicker, smarter and responsible decisions, while delivering greater value to their customers.

Proven Impact

Explore Our Case Studies & Latest Sucess Stories.

Reduced Jobsheets: India’s leading mobile company cut daily jobsheet volumes by 46% using innovative device detection modules.

Reduced Jobsheets: India’s leading mobile company cut daily jobsheet volumes by 46% using innovative device detection modules.

Improved Service Quality: Re-repairs reduced significantly through advanced diagnostics and competency management.

Improved Service Quality: Re-repairs reduced significantly through advanced diagnostics and competency management.

Optimized Inventory: Excess stock minimized, resulting in significant cost savings without service delays.

Optimized Inventory: Excess stock minimized, resulting in significant cost savings without service delays.

Decreased TAT: Efficient escalation and transfer processes reduced turnaround time across service categories.

Decreased TAT: Efficient escalation and transfer processes reduced turnaround time across service categories.

Prevention of Product Failures: Real-time feedback loops helped avoid large-scale failures at product launches.

Prevention of Product Failures: Real-time feedback loops helped avoid large-scale failures at product launches.